Short summary: SpaceX’s Starship is designed to be the world’s first fully reusable super-heavy launch system — a single architecture meant to carry people and cargo to low Earth orbit, the Moon, Mars, and beyond. This article explains the vehicle and its technology, traces the development and test program, summarizes recent regulatory and operational milestones, examines the economics and potential use cases (satellite launches, point-to-point Earth transport, lunar landings, Mars colonization), and explores the technical, environmental, and programmatic challenges that still stand between concept and routine operations.

1. Why Starship matters

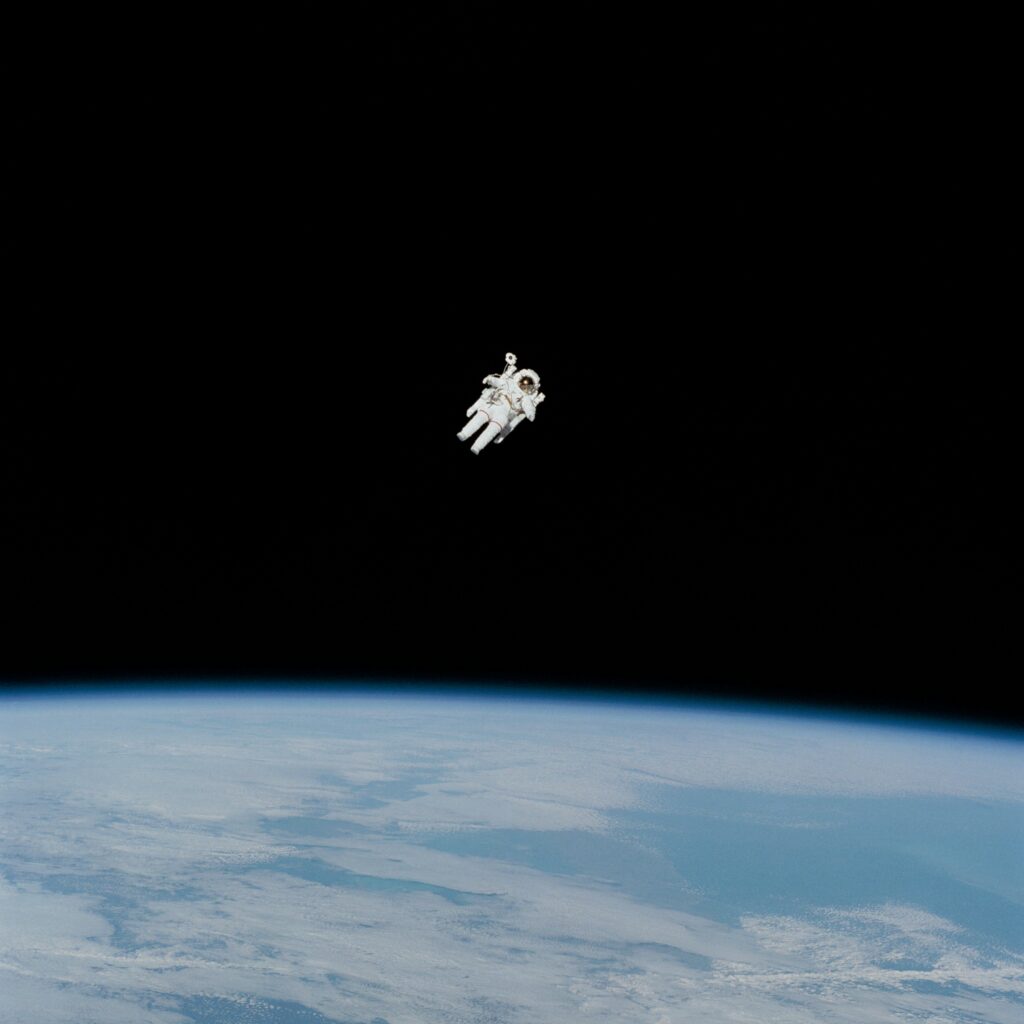

Starship is more than “another big rocket.” If it meets SpaceX’s goals of full reusability, high flight cadence, and dramatically lower marginal cost per ton, it would rewrite the economics of space activity in the same way that cheap, reliable air travel reshaped global mobility during the 20th century.

A truly reusable, high-capacity heavy lifter unlocks capabilities that are hard (or prohibitively expensive) with expendable rockets: very large space telescopes and interferometers assembled in orbit, space-based manufacturing of items that must be large, routine and affordable crew transfers, orbital refueling depots, and the ability to deliver tens or hundreds of tons of propellant and infrastructure to lunar or Martian surface sites. Economies of scale — mass production of identical ships and engines, rapid re-flight and low refurbishment time — are central to the vision.

Starship is also the backbone of SpaceX founder Elon Musk’s stated goal of making humans a multiplanetary species; it acts as the transport architecture for crew and cargo to Mars in his roadmap. But beyond visionary rhetoric, the vehicle has short- and medium-term commercial applications that make it strategically important even if human Mars flights remain decades away.

2. What exactly is Starship? (Design & hardware)

Starship is a two-stage, fully reusable launch system:

- Super Heavy booster (first stage) — a gigantic booster roughly 70–75 m tall for current Block designs, powered by a cluster of Raptor methane-oxygen engines that provide the initial lift and atmospheric ascent.

- Starship (second stage / spacecraft) — the upper stage that acts as both second-stage launcher and the long-duration spacecraft. It includes payload volume, heat-shield tiles for reentry, aerodynamic control surfaces, and its own Raptor engines (vacuum-optimized variants) for orbital maneuvers, landing, and potential in-space refueling use.

Both stages are built from stainless steel (chosen for cost, strength at cryogenic temperatures, thermal properties, and fabrication simplicity), and both are designed to return and land propulsively, dramatically lowering per-flight hardware costs if the rapid-turnaround operations can be achieved.

Key hardware facts often referenced: the design uses the Raptor family of full-flow staged combustion methane engines (Raptor 2 variants being the production target) and the booster configuration includes dozens of engines to produce the enormous thrust required. The exact engine counts and block performance targets have evolved as SpaceX iterates designs and test outcomes. (SpaceX, EOportal)

3. Performance targets and claimed capabilities

SpaceX’s widely reported performance goals for mature Starship variants include:

- Payload to low Earth orbit (block-dependent): on the order of tens to >100 metric tons to LEO in a fully reusable profile (higher in expendable mode).

- Gross vehicle height: approximately 120 m (Super Heavy + Starship).

- Full-system reusability: rapid re-flight with minimal refurbishment.

- In-orbit refueling: Starship is designed to accept propellant transfers in orbit so that a refueled Starship can depart Earth orbit with enough ΔV to reach the Moon or Mars and return.

Those targets are roadmap goals rather than current delivered performance; the program’s development model is iterative, with early flights validating subsystems, aerothermal regimes, and re-entry behaviors. For a sense of scale, SpaceX’s public pages and technical summaries have advertised payload ambitions in the ~100-ton class for later blocks, and independent reference materials list a roughly 120-meter tall vehicle and a wide payload bay that can host very large payloads and even whole modules. (EOportal, Skyrocket Space)

4. The development approach: “rapid iteration” and why it’s different

SpaceX’s Starship program follows the company’s high-cadence, iterative development philosophy: build, test, fail fast, learn, update, and fly again. This is visible in the company’s frequent prototype builds and the dozens of test articles that preceded integrated launches. Rapid iteration trades formal, exhaustive pre-flight qualification for empirical learning through flight and ground tests — a philosophy that accelerated Falcon development but also produces public failures.

Advantages:

- Problems are surfaced quickly and fixes can be validated in real flights.

- Learning accumulates rapidly — each flight contributes engineering data that refines subsequent designs.

Costs/tradeoffs:

- Public, high-profile failures create regulatory and political attention, generate environmental concerns, and can damage local stakeholder relations.

- Iteration in a system as large as Starship involves higher absolute costs and more complex safety considerations than smaller-scale programs.

The net effect: an aggressive schedule of prototypes and flights that aims to push key technologies (mass manufacturing of stainless steel shells, Raptor production scaleup, large-scale cryogenic systems, and re-entry thermal protection) into practical engineering maturity.

5. Key technologies that enable Starship

Starship’s aspirational capabilities hinge on a handful of technical advances:

Raptor engines (methane full-flow staged combustion): Raptor engines are central. Compared with older kerosene or hydrogen engines, Raptor’s methane propellant offers a balance of high performance, potential for in-space refueling using methane from local resources (in future Mars ISRU concepts), and cleaner combustion (less coking) that eases re-use. Mass production and reliability of Raptors are programmatic milestones. (SpaceX)

Large stainless-steel structures: Using stainless steel enabled rapid, low-cost fabrication at cryogenic temperatures and gives thermal mass benefits for certain reentry profiles but requires polishing, tile systems, and novel weld processes to meet operational durability.

Heat-shield & TPS (thermal protection system): The Starship upper stage uses a tiling system and active design to manage the intense aerothermal loads of re-entry from orbital or translunar trajectories.

Autonomous flight control & guidance for propulsive return: Precisely reigniting many engines for controlled reentry and a flip-maneuver landing (the iconic “belly-flip” to vertical landing) requires sophisticated control algorithms, reliable valve and plumbing systems, and redundancy.

In-orbit refueling techniques: If orbital refueling becomes routine, Starship’s operational envelope expands dramatically — enabling large payloads to be delivered to the Moon and beyond. Refueling requires precise orbital rendezvous, cryogenic propellant transfer in microgravity, boil-off control, and repeated docking operations at scale — all of which are non-trivial engineering tasks.

6. The test program to date — progress and public milestones

Starship’s flight test history has been highly public and consequential:

- Low-altitude hopper tests (2019–2021): numerous small-scale hopper flights validated basic control and landing techniques.

- High-altitude prototype flights (2020–2021): several Starship upper-stage prototypes reached tens of kilometers before controlled landing attempts; some succeeded, others failed — but each delivered data that informed flight-control and TPS designs.

- First integrated flight (April 20, 2023): SpaceX performed the first fully integrated Starship test (Super Heavy + Starship) that achieved liftoff and made it several minutes into flight before the vehicle was destroyed by flight-termination. That launch demonstrated integrated systems and set records for thrust while emphasizing the complexity of the fully stacked vehicle. (Wikipedia)

Throughout 2024 and 2025 the company continued rapid prototyping and multiple integrated test flights (numbered sequentially). Flight results have included both spectacular successes — long-duration engine burns, booster stage separation, and partial reentry operations — and setbacks like upper-stage failures and destructive explosions during ground testing and descent. SpaceX’s update channels list individual flight outcomes and root-cause investigations as the company iterates toward higher reliability. (SpaceX, Ars Technica)

7. Recent regulatory milestones and launch cadence

Large vehicles with public-safety and environmental footprints face substantial regulatory scrutiny. In 2024–2025 the U.S. Federal Aviation Administration (FAA) completed environmental reviews and issued findings that allowed increased cadence operations from SpaceX’s Boca Chica (Starbase) site, clearing the way for a larger number of annual test flights under certain mitigations. In May 2025 the FAA published decisions enabling SpaceX to scale up launches from the Texas site (approvals allowed up to ~25 launches per year under the Final Tiered Environmental Assessment and mitigated FONSI/ROD). That decision was a major enabler for SpaceX to pursue a much higher flight tempo. (FAA, SatNews)

Higher cadence matters: reusability economies require many cycles to amortize development and production costs; regulatory approvals and mitigation measures are therefore prerequisites for SpaceX’s business model to function at scale.

8. Operational challenges still in play

Starship’s promise is enormous, but so are the engineering hurdles:

Reliability & engine orchestration: For booster return and upper-stage operations, SpaceX must achieve highly reliable multi-engine ignitions, throttle control, and reignitions. Engine failures at critical flight phases create cascading failure modes.

Heat-shield durability and TPS refurbishment: The upper stage experiences severe heating on reentry. A low-cost, rapid-turn heat-shield solution is essential — neither heavy tiles that require time-consuming inspection nor expensive single-use TPS will support rapid re-flight economics.

Orbital refueling engineering: Transferring cryogenic methane/LOX in microgravity without unacceptable boil-off losses or contamination is a major systems integration problem that requires precise hardware, thermal control, and operational discipline.

Manufacturing scale & supply chain: Achieving mass production of dozens of Raptors and many stainless shells requires supply-chain diversification, tooling, workforce scaling, and quality control at an industrial level — a non-trivial task for any aerospace firm.

Environmental and community concerns: Range safety, sonic booms, debris, and pad accidents have local environmental consequences. Incidents such as ground explosions and debris scatter have prompted local protests and cross-border diplomatic attention in the past; managing these community and environmental impacts is necessary for sustainable operations.

Flight-test risk profile and public scrutiny: High-visibility failures attract regulatory, public, and political oversight. SpaceX has navigated multiple regulatory interactions and investigations to continue testing while addressing safety and environmental issues.

9. Recent operational incidents and learning moments

2025 included a mix of successes and high-profile anomalies. Some flights completed long engine burns and demonstrated booster staging sequences, while other upper-stage failures and ground test explosions led to loss of vehicles and investigations. SpaceX typically posts follow-up engineering analyses and implements design changes (for example, fuel-system redesigns or updated plumbing/valving) after root-cause identification. Those changes are part of the iterative evolution of the program and underscore the empirical nature of the development process. (Ars Technica, SpaceX)

Importantly, each anomaly informs hardware layout (propellant header design, tank pressurization strategies), software safety nets (fault detection and automated abort logic), and operational procedures (pad safety, pre-flight testing regimens). Over time, this cycle reduces the probability of repeat failures and supports the transition toward routine mission operations.

10. Starship’s business cases — why customers might care

Massive satellite deployment: For mega-constellations and very large satellites, the capability to loft tens to a hundred+ tons in a single launch simplifies deployment and reduces per-satellite integration complexity. Starship could enable the emplacement of satellite constellations in a fraction of the number of launches needed with current rockets.

Large space infrastructure & in-orbit assembly: Starship can launch very large payloads or entire modules for space stations, telescope mirrors, or manufacturing platforms. The ability to loft big pieces reduces the need to assemble many small elements in orbit.

Human spaceflight: The vehicle aims to carry large crews and supplies — potentially enabling sustained Artemis lunar surface rotations, large science crews, or eventual Mars settlements.

Point-to-point Earth transport (conceptual): SpaceX has publicized the idea of rapid Earth travel via suborbital Starship hops — crossing continents in under an hour. Practical economic, regulatory, noise, and safety considerations make this a long-term speculative market, but it illustrates the range of applications unlocked by very rapid, high-capacity vehicles.

Lunar logistics and NASA partnerships: Starship was selected under NASA’s Human Landing System (HLS) process as the lander architecture for an Artemis lunar crew descent variant; the Starship HLS variant is being adapted to the requirements for lunar surface operations and NASA certification processes. This NASA relationship gives Starship an explicit government customer for crewed lunar missions (subject to integration milestones, safety certifications, and mission demonstrated readiness). (NASA)

11. Economic model — costs, cadence, and the unit-economics problem

Starship’s business case rests on dramatically reducing the cost per kilogram to orbit via:

- Low marginal cost of re-flown vehicles (versus single-use rockets).

- High payload per launch (fewer launches per total mass delivered).

- High flight cadence (spreading fixed infrastructure and R&D across many flights).

Mass production and economies of learning (manufacturing yields improve, cycle times fall) are essential. If SpaceX can perform dozens of flights per year and re-use hardware quickly with only minor refurbishment, the per-flight cost can fall sharply. But this outcome requires the confluence of high reliability, quick turnaround processes, and a robust stream of demand from commercial, civil, and national customers.

A parallel question is funding the ramp: building Orbital/launch infrastructure, mass production lines for Raptors, and launch-site facilities demands substantial capital before the returns from lower per-launch costs materialize. SpaceX has financed much of the program internally, backed by revenue from Falcon launches, Starlink satellite revenues, and private investment. Public contracts (like NASA’s HLS work) provide additional cash flow but also add certification and safety overhead.

12. Starship and NASA: the Artemis equation

NASA selected a Starship-derived Human Landing System to carry astronauts from lunar orbit to the surface, marking a major civil-space tie between SpaceX and the agency. Under that partnership, SpaceX must demonstrate uncrewed test flights, demonstrate lunar descent and ascent profiles, meet stringent safety and mission assurance requirements, and integrate with the broader Artemis architecture (Orion, Gateway, orbits, mission timelines). NASA’s certification process includes strict verification and validation steps, and the agency’s schedule for crewed landings depends on SpaceX meeting milestones and system readiness.

This partnership validates Starship as more than a commercial vehicle — it’s being matured for human missions — but also imposes a layer of public accountability and schedule risk that the program must navigate carefully. (NASA)

13. Environmental, regulatory, and community impacts

Starship’s scale and testing cadence required environmental review. The FAA led a Tiered Environmental Assessment process and released mitigated findings and decisions allowing increased launches from Boca Chica under certain conditions — a notable milestone. Environmental concerns include sonic impacts, debris fallout in rare anomalies, coastal ecosystem effects, and emissions (plume chemistry and local contamination from pad incidents). Community engagement, mitigation commitments, and cross-border diplomacy (when debris or sonic effects reach neighboring regions) are operational realities SpaceX must manage as flights continue. (FAA, Space Force Starship EIS)

14. Global and geopolitical implications

If Starship achieves routine heavy-lift reusability, national space programs and commercial players will adapt: extremely large payloads could be launched by a private actor, lowering barriers to entry for large science and infrastructure projects. This shifts strategic leverage and raises questions about access and governance in orbit and cis-lunar space. National security stakeholders are already sensitive to the ability to deliver very large payloads quickly; regulation and export controls will evolve to match the new capabilities.

Moreover, the ability to send massive cargos economically makes the Moon and cislunar space more accessible to commercial activity (ISRU, mining, tourism), increasing the need for clear rules about property, resource rights, and safety in international law and bilateral agreements.

15. The Mars vision — can Starship enable settlement?

SpaceX presents Starship as the transport architecture for future Mars colonization. The idea: use orbital refueling depots and multiple Starship vehicles to send many tons of cargo and eventually humans to establish a self-reliant base on Mars.

Technically, the pathway requires:

- high confidence in vehicle reliability,

- demonstrated long-duration life-support and habitat technologies,

- robust in-situ resource utilization (ISRU) capability on Mars to produce propellants and supplies from local resources,

- closed-loop logistics for long missions and contingencies,

- political and economic willingness to sustain long, risky endeavors.

At present, Mars settlement remains a multi-decadal aspiration. The plausibility argument is that a reusable, high-capacity, and relatively low-cost transport system like Starship is a necessary — but not sufficient — condition for settlement. Mars ISRU, surface power, radiation shielding, and human systems all must mature in parallel.

16. Where the program stands today (operational snapshot & near-term outlook)

As of mid-2025, SpaceX has flown multiple integrated Starship tests, learned from failures, and made design updates while maintaining an aggressive test tempo. The FAA’s environmental decisions in 2024–2025 permitted a significant ramp in launch cadence from the Boca Chica site, and SpaceX scheduled additional integrated flights into late 2025 as the program iterates. Flight outcomes in 2025 included both long-duration flight segments and upper-stage failures that prompted rapid redesigns — the hallmark of an empirical, flight-test driven program. SpaceX also continued to expand production facilities (the “Starfactory”) and pursued a multi-site approach with plans for Cape Canaveral operations to support broader U.S. launch demand. (SpaceX, Space, MySA)

(Important factual anchors: the first integrated flight of a full Starship vehicle occurred on April 20, 2023; SpaceX’s vehicle uses clustered Raptor engines and stainless-steel construction; and the FAA’s environmental approvals in 2025 allowed SpaceX to increase flights from Starbase under mitigations. These milestones are documented in mission reports and agency releases.) (Wikipedia, SpaceX, SatNews)

17. Risks, showstoppers, and realistic failure modes

No program of this ambition is risk-free. Major risk categories include:

Unresolved thermal protection / TPS lifetime: If the heat-shield/system requires extensive post-flight refurbishment, turnaround times and costs will remain high.

Engine supply and reliability constraints: Raptors are complex engines; high-volume manufacturing with acceptable quality needs supply-chain and production discipline. A persistent failure mode in the engine or feed systems can ground fleets.

Orbital propellant transfer infeasibility or inefficiency: If cryogenic orbital refueling proves too lossy or operationally fragile, many of Starship’s promised mission profiles (fully reusable lunar/Mars missions) will be harder to realize.

Regulatory or political pushback: Environmental incidents, local opposition, or geopolitical restrictions could slow flight cadence or limit operational sites—affecting economics.

Customer demand mismatch: The vehicle’s economics are contingent on many flights. If sufficient commercial and civil demand for high-mass launches does not materialize quickly, the capital and operating model must adapt.

These risks are not theoretical — they are the same practical problems that have slowed other ambitious aerospace programs. Each is addressable, but each requires time, money, and a long-term tolerance for iterative learning.

18. What success looks like (practical milestones to watch)

If you want to judge Starship’s progress in the next several years, watch for these measurable milestones:

- Repeated successful integrated flights with safe booster recovery and multiple successful re-entries of the upper stage without prohibitive refurbishment costs.

- Reliable Raptor production and demonstrable per-engine reliability numbers.

- A routine, demonstrated method for orbital cryogenic refueling that works on repeated missions.

- A well-documented path to Crew-certified operations (for NASA HLS and eventual commercial human transport), including uncrewed lunar demonstrator success.

- An accelerating cadence: dozens of flights per year with decreasing turnaround time and demonstrated cost reductions per flight.

When several of those indicators are visible and persistent, the vehicle moves from “experimental” into “operationally transformative.”

19. Broader impacts — science, industry, and society

Science: Large, inexpensive lift allows new classes of science missions — enormous interferometers, very large space telescopes, multi-ton sample returns, and complex planetary surface infrastructures that would otherwise be unaffordable.

Industry: Space infrastructure markets (manufacturing, assembly, in-orbit servicing, space tourism) become more viable. New supply chains—metal fabrication, high-volume turbomachinery, cryogenics—scale up with cross-sector economic spillovers.

Society: Lowered launch cost and routine space access democratize space projects, but they also raise governance questions about orbital debris, resource extraction, and environmental impacts. Balancing access with stewardship will be a central policy challenge.

20. Frequently asked questions (short answers)

Q: When will Starship be “operational”?

A: Operational maturity is a function of reliability, cadence, and economics. Even with rapid iteration, full operational status (routine flights with low refurbishment) will likely require multiple years of consistent successes after the program’s most difficult technical milestones are closed.

Q: Can Starship carry humans to the Moon or Mars soon?

A: Technically Starship is designed with humans in mind, and NASA awarded Starship an HLS contract. But crewed missions require extensive uncrewed demonstrations, safety certification, and human-systems validation. A conservative schedule anticipates several years between successful integrated tests and certified crewed lunar operations; Mars remains a longer-term endeavor.

Q: Will Starship replace Falcon 9/Falcon Heavy?

A: SpaceX is likely to operate multiple vehicles in parallel for some time. Falcon 9 is a proven, flexible vehicle with decades of flights planned; Starship is aimed at high-mass markets that complement rather than directly replace Falcon capabilities immediately.

Q: Is Starship environmentally safe?

A: The program’s environmental footprint is under active assessment. FAA environmental decisions include mitigations; local impacts are being managed via permitting and community engagement. Accidents and pad explosions have demonstrated that environmental incidents can occur, which is why strict oversight and community involvement remain essential.

21. How to follow ongoing developments

Authoritative sources and timely reads:

- SpaceX updates and webcast pages (for live launch coverage). (SpaceX)

- FAA Final Tiered Environmental Assessment and FONSI/ROD documents for regulatory decisions. (FAA)

- Spaceflight news outlets (Space.com, Spaceflight Now) and major newspapers for independent reporting on flights and investigations. (Space, Spaceflight Now)

22. Final thoughts — big promise, harder reality

Starship is one of the most audacious aerospace programs in decades. Its promise — true, rapid, and affordable access to space at scales never before seen — could transform human activity in orbit, on the Moon, and eventually on Mars. But that promise sits behind a steep mountain of engineering, regulatory, environmental, and economic challenges.

History tells us that audacious engineering succeeds when repeated, carefully instrumented learning cycles are combined with patient investment, strong supply chains, and transparent safety cultures. SpaceX’s approach puts those learning cycles on public display: spectacular failures, fast improvements, and occasional rapid, unexpected progress.

If Starship succeeds, the world will gain capabilities we are only just beginning to imagine. If it fails to meet key objectives, much of the same technology (Raptor engines, stainless manufacturing, high-thrust design lessons) will still influence future heavy-lift architectures. Either way, the program will push the frontiers of rocketry and industrial spaceflight for years to come.

Key recent references used in this article (for further reading and verification):

- Historical first integrated Starship flight and test discussion. (Wikipedia)

- SpaceX official Starship vehicle overview (specs, Raptor engine use). (SpaceX)

- FAA Final Tiered Environmental Assessment and mitigated FONSI/ROD enabling increased cadence at Boca Chica. (FAA)

- Spaceflight and space press coverage of upcoming integrated flights and recent 2025 test results (Flight 10 targeting Aug. 24, 2025 as an example). (Space, MySA)

- NASA Human Landing System (HLS) program pages noting Starship HLS selection and role for Artemis lunar missions. (NASA)

If you’d like, I can now:

- Convert this into WordPress-ready HTML with headings, image placeholders, and an SEO meta description.

- Produce a shorter 700–900 word executive summary for social sharing.

- Create graphics: a one-page infographic comparing Starship to existing heavy-lift rockets, and a timeline of test flights and regulatory milestones.

Which would you like next?